stainless steel wedge wire screen

stainless steel wedge wire screen

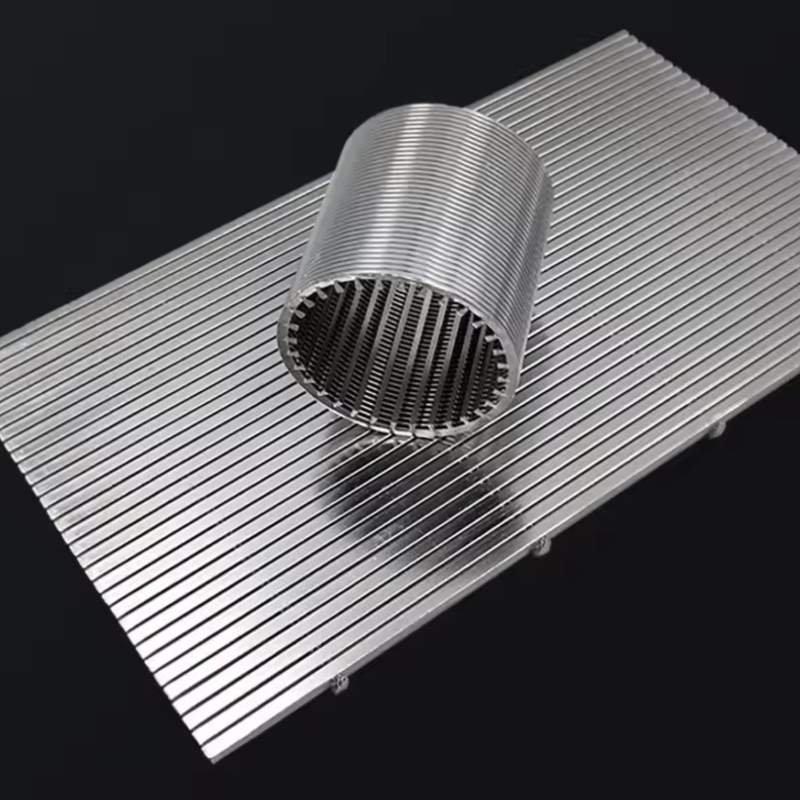

Stainless steel wedge wire screens are precision-engineered metal mesh components designed for screening and filtration applications. They are extensively applied in processes such as screening, filtering, dewatering, and desludging across multiple industries. Known for their exceptional strength, rigidity, and load-bearing capacity, these screens can be fabricated into a variety of durable and rigid screening or filtration systems.

Material: High-quality stainless steel wire.

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

stainless steel wedge wire screen Description

Stainless steel wedge wire screens, also known as profile wire screens, are precision-engineered filtration and separation components widely used across industrial applications. Manufactured by winding stainless steel wire into a V-shaped profile and welding it onto supporting rods, this design ensures a continuous slot opening that provides superior filtration efficiency and structural integrity.

Made from high-quality stainless steel wire, wedge wire screens are highly resistant to corrosion, high temperatures, and mechanical wear, making them suitable for demanding working environments. They feature high strength, rigidity, and load-bearing capacity, while the unique V-shaped slot structure minimizes clogging and allows for excellent flow distribution.

Stainless steel wedge wire screens can be fabricated into a wide range of shapes and sizes, including panels, baskets, cylinders, cones, and nozzles, tailored to specific engineering needs. They are extensively applied in water treatment, mining, coal, petroleum, chemical processing, food and beverage, sugar production, pulp and paper, and environmental protection industries for screening, filtration, dewatering, and desludging operations.

stainless steel wedge wire screen Features

1. Non-Clogging Design – The continuous V-shaped slot structure ensures effective filtration while minimizing blockages, maintaining consistent flow.

2. High Strength & Durability – Manufactured from stainless steel with advanced welding technology, offering excellent mechanical strength and long service life.

3. Corrosion & Heat Resistance – Superior resistance to rust, chemical corrosion, and high temperatures, making it suitable for harsh industrial environments.

4. Accurate Slot Control – Slot openings can be precisely controlled to achieve desired filtration accuracy, ranging from coarse screening to fine separation.

5. Efficient Flow Capacity – Large open area provides smooth flow distribution, reducing pressure loss and improving filtration efficiency.

6. Versatile Shapes & Sizes – Available in panels, cylinders, baskets, cones, and custom designs to meet diverse application requirements.

7. Low Maintenance – Smooth surface and strong structural stability reduce wear, deformation, and cleaning frequency.

Note: Please leave your email address, our professionals will contact you as soon as possible!