Perforated Metal Sheets

Perforated Metal Sheets

Perforated Metal Sheets refers to punching holes of different shapes on the same material to meet different needs.

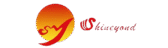

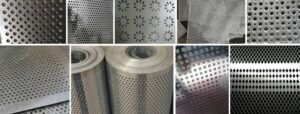

The main specifications of punching mesh are rectangular hole, square hole, diamond hole, round hole, oblong hole, hexagonal hole, cross hole, triangular hole, long waist hole, plum blossom hole, fish scale hole, pattern hole, splayed mesh, herringbone Holes, five-pointed star holes, irregular holes, drum holes, special-shaped holes, louver holes, etc.

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

Perforated Metal Sheets Description

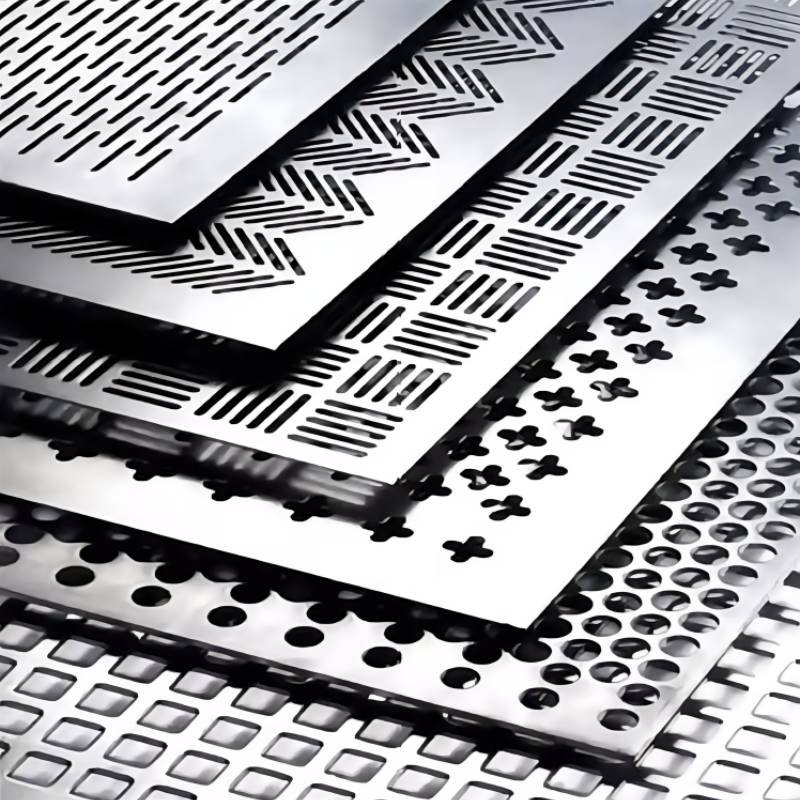

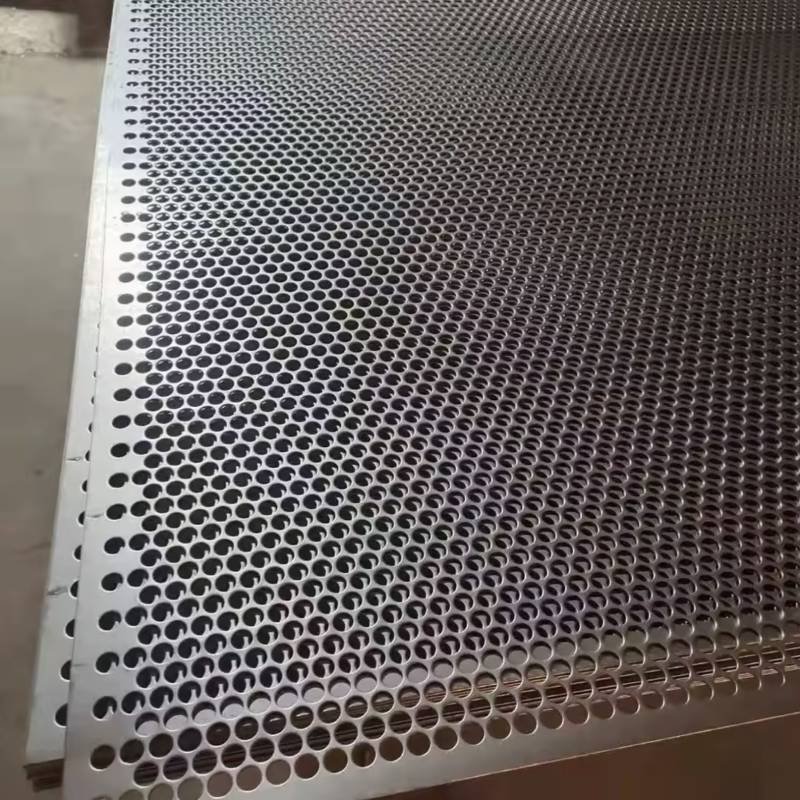

Perforated metal sheets are flat metal panels that have been uniformly punched, stamped, or laser-cut with various hole shapes and patterns, such as round, square, slotted, or decorative designs. They are manufactured from a wide range of materials including stainless steel, galvanized steel, aluminum, carbon steel, and copper to meet different application needs.

These sheets combine strength, versatility, and aesthetics, making them ideal for both functional and decorative purposes. With features such as excellent ventilation, light filtration, sound absorption, and structural support, perforated metal sheets are widely used in construction, architecture, interior design, industrial filtration, machinery protection, and furniture production.

Perforated metal sheets not only provide durability and corrosion resistance but also enhance safety and visual appeal. Their customizable hole patterns, thicknesses, and sizes allow them to meet specific project requirements, offering both practical performance and design flexibility.

Perforated Metal Sheets Practical use

Perforated metal sheets have a wide range of applications across construction, industry, and daily life. In the building sector, they are commonly used as sound-absorbing materials for ceilings and wall panels, as well as decorative perforated panels for stairs, balconies, and eco-friendly furniture such as tables and chairs. In industrial and agricultural applications, they serve as protective covers for machinery, speaker grills, filtration and screening plates for food, feed, grinding, and mining operations, including I-shaped sieves for mines. In household and commercial use, they are widely applied in stainless steel fruit baskets, food covers, trays, and other kitchenware, as well as shelf nets for malls, decorative display stands, ventilation panels for grain depots, and drainage filters for football field lawns.

In the electronics industry, perforated mesh is used for dustproof and soundproof enclosures in audio systems and other equipment. Thanks to its unique properties, perforated sheets are also extensively applied in chemical machinery, pharmaceutical equipment, food and beverage processing, cigarette machinery, harvesters, dry-cleaning machines, ironing tables, mufflers, refrigeration systems (including central air-conditioning), handicraft production, papermaking, hydraulic components, and filtration devices.

Most of the raw materials used for punching mesh are: stainless steel, low carbon steel plate, galvanized PVC cold rolled coil, etc.

The types are divided into: pattern punching mesh, forming punching mesh, extra thick punching mesh, extra thin punching mesh, micro hole punching mesh, wire cutting punching mesh. Laser punching mesh, etc.

Perforated Metal Sheets specification

The main specifications of punching mesh are rectangular hole, square hole, diamond hole, round hole, oblong hole, hexagonal hole, cross hole, triangular hole, long waist hole, plum blossom hole, fish scale hole, pattern hole, splayed mesh, herringbone Holes, five-pointed star holes, irregular holes, drum holes, special-shaped holes, louver holes, etc.

1. Coil thickness 0.2mm-1mm, length 20m.

2. Aperture diameter 1.5mm-10mm.

3. The thickness of the sheet is 0.2mm-20mm; width*length≤1.5m*5m.

4. Aperture diameter 0.5mm-200mm.

Perforated Metal Sheets Punching method

1. Continuous punching in the same direction – By partially overlapping the processing area with a rectangular punching die, this method is suitable for producing long holes, edge trimming, and similar applications.

2. Continuous forming – A technique used to create shapes larger than the punching die itself, such as oversized shutters, rolling bars, and step patterns.

3. Nibbling – Involves using a small round die to continuously punch arcs with short intervals, allowing curved shapes to be formed.

4. Multi-directional continuous punching – Employs a small punching die to gradually create large holes through repeated operations in multiple directions.

5. One-time forming – A single shallow drawing and forming process performed according to the mold’s shape, completing the required structure in one step.

6. Single punch – Direct punching performed once to produce patterns such as linear arrays, arcs, circular distributions, or grid-like holes.

7. Array forming – Enables the processing of multiple identical or varied workpieces on a single large plate efficiently.

Packing method: bulk cargo packing, wooden box packing or wooden pallet packing

Note: Please leave your email address, our professionals will contact you as soon as possible!