Low Carbon Steel Perforated Metal Mesh

Low Carbon Steel Perforated Metal Mesh

Low Carbon Steel Perforated Metal Mesh is a perforated metal mesh product made of low carbon steel with a carbon content of 0.10% to 0.30%. Low carbon steel perforated metal mesh has low strength and hardness, good plasticity and toughness, and is not easy to break.

Material: low carbon steel. Low carbon steel, also known as mild steel, contains carbon from 0.10% to 0.30%. Low carbon steel is easy to accept various processing such as forging, welding and cutting

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

Low Carbon Steel Perforated Metal Mesh Description

Low Carbon Steel Perforated Metal Mesh is a type of perforated metal product made from low carbon steel with a carbon content of 0.10% to 0.30%. This material provides lower strength and hardness compared to other steel types, but it offers excellent plasticity and toughness, making it flexible, durable, and resistant to breakage.

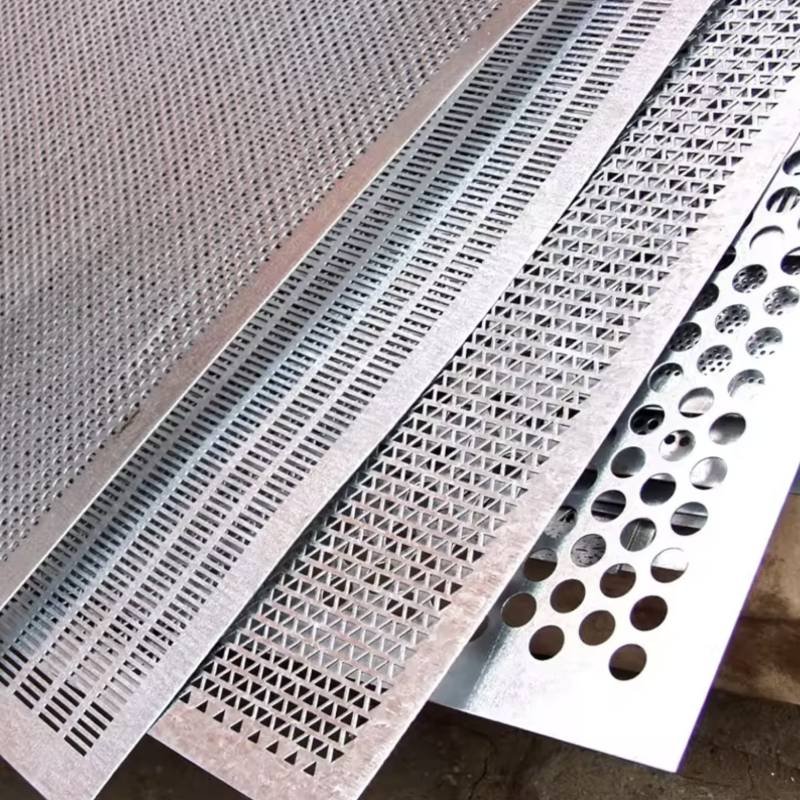

The mesh features uniformly punched holes that allow for effective ventilation, drainage, filtration, and light passage, while maintaining structural integrity. Due to its workability and versatility, low carbon steel perforated mesh is widely used in architectural decoration, industrial equipment covers, protective panels, shelving, and ventilation systems.

Its ease of cutting, bending, and forming, combined with cost-effectiveness, makes it a practical choice for both industrial and commercial applications.

Material: low carbon steel. Low carbon steel, also known as mild steel, contains carbon from 0.10% to 0.30%. Low carbon steel is easy to accept various processing such as forging, welding and cutting, and is often used to manufacture chains, rivets, bolts, shafts, etc. Carbon steel with a carbon content of less than 0.25% is also called soft steel because of its low strength, low hardness and softness. It includes most ordinary carbon structural steels and some high-quality carbon structural steels, most of which are used for engineering structural parts without heat treatment, and some are used for mechanical parts requiring wear resistance after carburizing and other heat treatments.

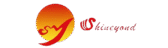

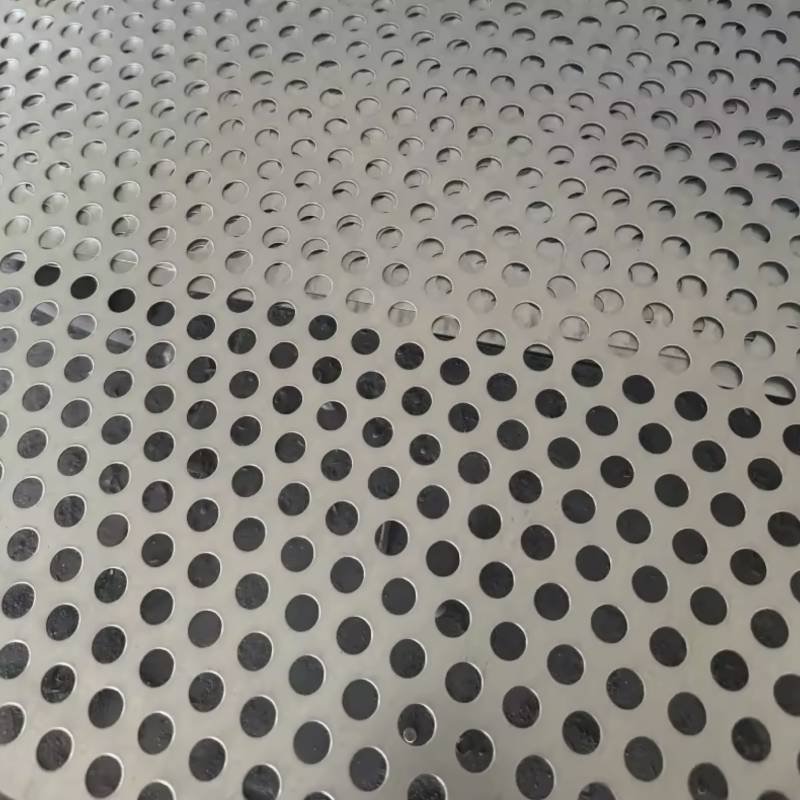

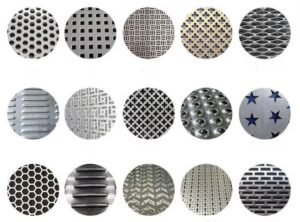

Hole type: long hole, round hole, square hole, triangular hole, fish scale hole, bridge hole, diamond hole, pentagonal hole, hexagonal hole, figure-eight hole, cross hole, nail hole, plum blossom hole, herringbone hole, tool Character holes and other special-shaped holes.

Surface treatment: PVC dipping (plastic spraying, plastic coating), hot-dip galvanizing, electro-galvanizing, spraying anti-rust paint, etc.

Low Carbon Steel Perforated Metal Mesh Features

1. Material Composition – Made from low carbon steel with 0.10%–0.30% carbon content.

2. Excellent Plasticity & Toughness – Flexible and ductile, resistant to breakage under stress.

3. Lower Hardness & Strength – Easier to work and form compared to high-carbon steel.

4. Uniform Perforations – Provides consistent ventilation, drainage, filtration, and light passage.

5. Corrosion Resistance – Can be galvanized, powder-coated, or painted for enhanced protection.

6. Customizable Options – Hole size, pattern, sheet thickness, and surface finish can be tailored to project needs.

7. Ease of Fabrication – Easy to cut, bend, weld, and shape for various applications.

8. Versatile Applications – Suitable for architectural decoration, industrial equipment covers, protective panels, shelving, and ventilation systems.

9. Cost-Effective – Provides a practical balance between performance, workability, and price.

Low Carbon Steel Perforated Metal Mesh Uses

Low Carbon Steel Perforated Metal Mesh is widely used in environmental protection sound barriers for transportation and municipal facilities, including highways, railways, and subways in urban areas. It is also applied as sound-insulating and noise-absorbing panels for building walls, generator rooms, and factory buildings, as well as acoustic materials for ceilings and wall panels.

In architecture and interior design, it serves as decorative perforated plates for stairs, balconies, and eco-friendly tables and chairs, combining aesthetics with functionality. In the industrial sector, it is used for protective covers for machinery, speaker grille panels, grinding screens, mine screens, and I-type screens for grain and feed processing.

Additionally, it is suitable for kitchen equipment such as stainless steel fruit baskets, food covers, and trays, as well as commercial applications like shelving nets in shopping malls, decorative display racks, and ventilation meshes for grain warehouses.

Note: Please leave your email address, our professionals will contact you as soon as possible!