Welded Wire Mesh

Welded Wire Mesh

Welded wire mesh is manufactured by welding high-quality low-carbon steel wires, followed by surface treatments such as cold galvanization (electroplating), hot-dip galvanization, or PVC coating to enhance durability and corrosion resistance.

Welded wire mesh is widely used in industry, agriculture, construction, transportation, mining and other industries.

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

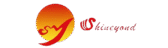

Welded Wire Mesh Description

Welded Wire Mesh, also known as external wall insulation wire mesh, galvanized wire mesh, galvanized welded wire mesh, steel wire mesh, row welded mesh, touch welded mesh, construction mesh, exterior wall insulation mesh, decorative mesh, barbed wire mesh, square mesh, screen mesh, and anti-crack net, is a durable and versatile product made by welding high-quality low-carbon steel wires into a uniform grid. To enhance strength, corrosion resistance, and longevity, the mesh undergoes surface treatments such as hot-dip galvanization, electroplating, or PVC coating. Widely used in construction, fencing, reinforcement, industrial applications, and decorative projects, welded wire mesh offers excellent stability, durability, and ease of installation, making it an essential material for both functional and aesthetic purposes.

Welded Wire Mesh Parameter

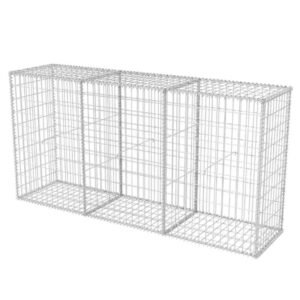

Welded Wire Mesh Application

Welded Wire Mesh is extensively used across industry, agriculture, construction, transportation, mining, and other sectors. Common applications include machine guards, livestock and garden fences, window and passage fences, poultry cages, egg baskets, home and office storage baskets, waste bins, and decorative purposes.

In construction, it plays a crucial role in building exterior walls, concrete reinforcement, and high-rise residential buildings, particularly within thermal insulation systems. During installation, hot-dip galvanized welded mesh is embedded inside the outer mold of the wall to be poured, allowing the insulation board and wall to cure together. Once the formwork is removed, the insulation board and wall form a fully integrated structure, enhancing stability, durability, and thermal performance.

Note: Please leave your email address, our professionals will contact you as soon as possible!