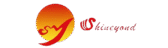

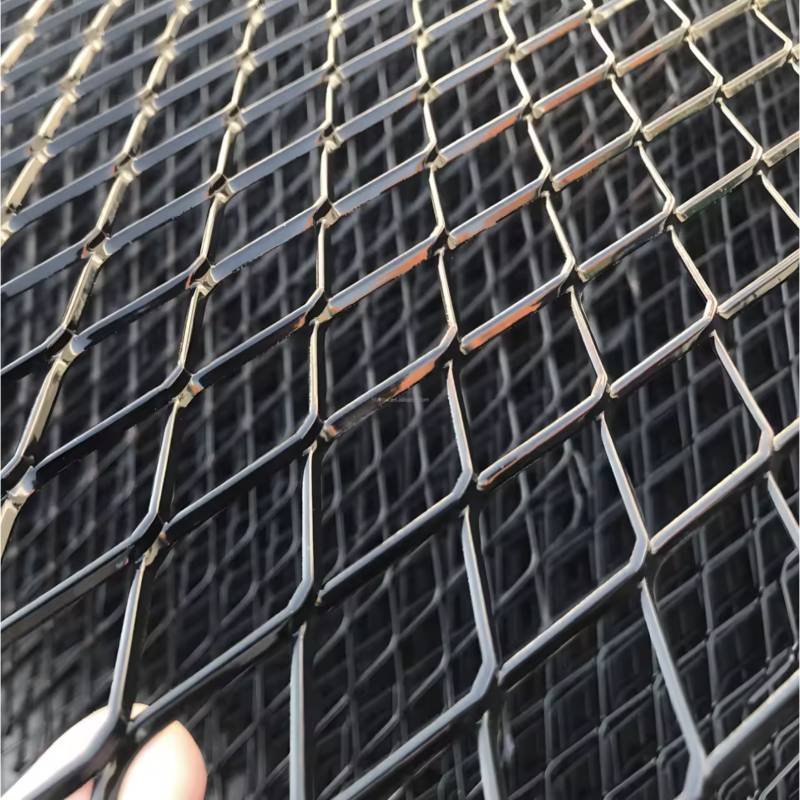

Heavy Duty Expanded Metal Mesh

Heavy Duty Expanded Metal Mesh

Plate thickness (4.0mm~8.0mm)

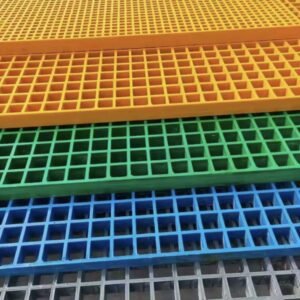

Mainly used in factories, mines, ships, construction sites, aerial walkways, concrete reinforcement, road laying, and outdoor barriers, all of which can be widely used

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

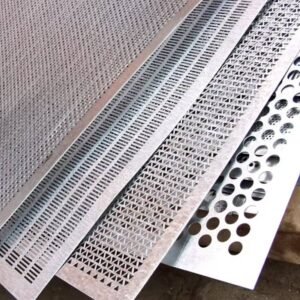

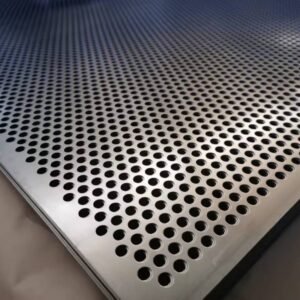

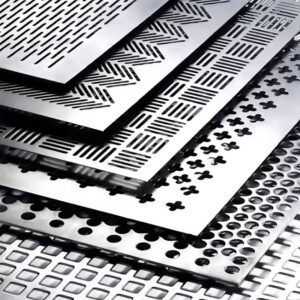

Heavy Duty Expanded Metal Mesh Description

Heavy Duty Expanded Metal Mesh is a robust and durable metal mesh product designed for applications requiring high strength and load-bearing capacity. Manufactured by cutting and stretching heavy gauge metal plates, it forms a rigid diamond-shaped mesh structure that offers excellent stability and long service life. This type of expanded metal is ideal for heavy industrial environments where durability, safety, and reliability are essential.

Surface treatment

1. Dipping is a plastic coating process in which a plastic is coated on a substrate (usually metal). This process does not need mold, low processing cost, easy forming, can process a variety of shapes and other characteristics are widely used.

2. Hot dip galvanizing: also known as hot dip galvanizing, refers to zinc in a high temperature liquid state, divided into several processes, the liquid state of zinc wrapped in the surface of the product, after cooling to form anodic coating.

3. Cold galvanizing: cold galvanizing, also known as electric galvanizing, is the use of electrolytic equipment to remove oil, pickling, after the product into the composition of zinc salt solution, and connected to the negative electrode of the electrolytic equipment, placed on the opposite side of the product zinc plate, connected to the positive electrode of the electrolytic equipment on the power supply, the use of current from the positive electrode to the negative electrode directional movement will be deposited on the product a layer of zinc, cold galvanizing products are first processed after galvanized.

The difference between hot dip galvanizing and cold dip galvanizing

1. The cold galvanized coating is uniform and the coating thickness is very thin; The hot-dip galvanized coating is thick but uneven.

2. Cold galvanizing has a bright appearance, while hot galvanizing has a darker color.

3. The cold plating coating has poor corrosion resistance due to its thin thickness; The hot-dip coating is thicker and forms a participating layer with the base metal, resulting in good corrosion resistance.

Note: Please leave your email address, our professionals will contact you as soon as possible!