Steel Grating

Steel Grating

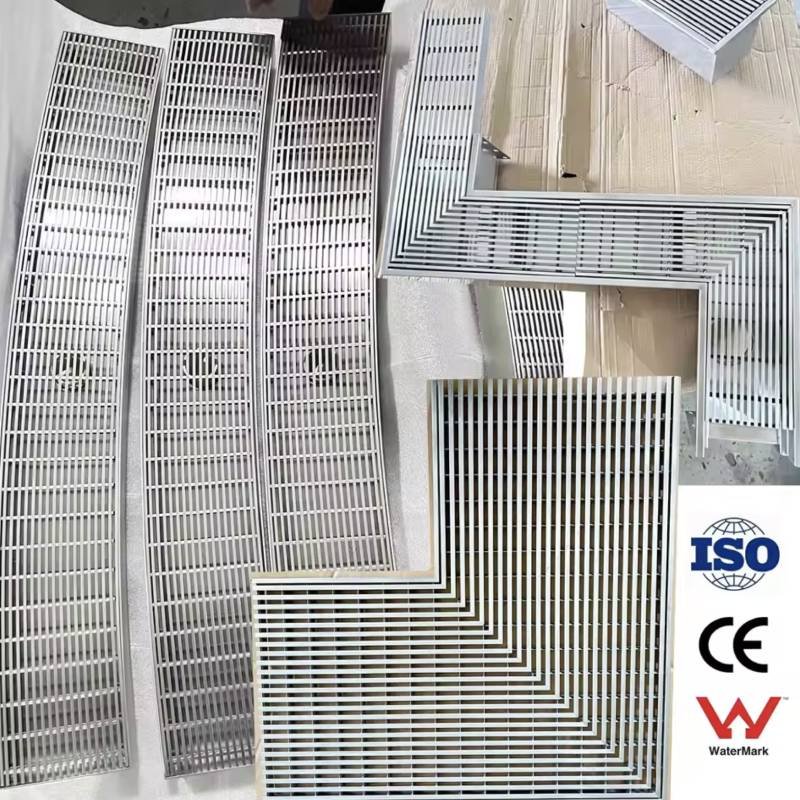

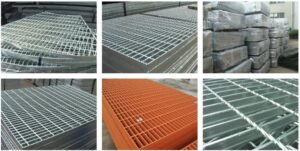

Steel Grating, also called grid grating, is made by cross-arranging flat steel and bars (square, round, or twisted steel) and welding them into a square lattice. It is mainly used for gutter covers, steel platforms, and stair treads, providing strength, durability, and load-bearing support.

Standard: YB/T4001.1-2019

- Source factory price

- Assembling quantity guarantee

- Provide customized services

- hkygs000@gmail.com

- +86 13016023760

Product Details

Steel Grating Description

Steel Grating, also called grid grating, is typically made of carbon steel with a hot-dip galvanized surface to prevent oxidation, and can also be made from stainless steel. It is constructed by cross-arranging flat steel and bars (square, round, or twisted steel) and welding them into a square lattice.

Steel grating provides excellent ventilation, lighting, heat dissipation, anti-skid, and explosion-proof properties, making it ideal for gutter covers, steel platforms, stair treads, and other industrial or commercial applications where strength, durability, and safety are essential.

Standard: YB/T4001.1-2019

Steel Grating Parameters

Materials of Steel Grating

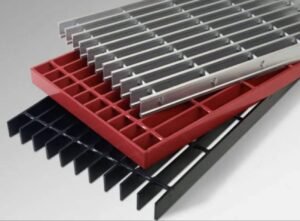

Steel grating is commonly made from four main types of materials: carbon steel, galvanized steel, stainless steel, and aluminum alloy.

Carbon Steel Grating is the most common type, made primarily of carbon and iron. It is cost-effective and widely used in general industrial and commercial applications.

Galvanized Steel Grating is carbon steel coated with a zinc-iron alloy, providing excellent corrosion resistance and oxidation protection, making it suitable for outdoor and harsh environments.

Stainless Steel Grating is manufactured from high-temperature and pressure-resistant stainless steel, ideal for special environments such as marine engineering and coastal construction.

Aluminum Alloy Grating is a lightweight, corrosion-resistant material with good high-temperature resistance and strength, making it suitable for air purifiers, air ducts, and ventilation systems.

The first is made of raw flat steel and twisted steel cross-welded without surface treatment of steel grating called “carbon steel grating” also known as “black iron grating”.

The second is the surface of the hot-dip galvanized appearance of silver-white steel grating, the practice is to “carbon steel grating” into the galvanized pool for soaking so that the galvanized layer attached to the surface of the product has a certain anti-corrosion and anti-rust effect.

The third is stainless steel, stainless steel material is divided into 201 stainless steel material / 304 stainless steel material, the difference is that 201 stainless steel touch water and easy to rust, 304 stainless steel is more durable, is commonly used food grade 304 stainless steel.

The fourth type of painted steel grating is also known as “spray steel grating” is to use “carbon steel grating” surface with a color of the spray or paint surface treatment, presenting a different color role, anti-corrosion and rust resistance in general.

Galvanized steel grating, stainless steel grating, plug-in steel grating, non-slip steel grating, heavy duty steel grating, composite steel grating, profiled steel grating, step plate, trench cover plate.

Steel Grating Classification

1. According to the welding method, can be divided into: pressure welding type, phase embedded type, through the lock type and through the welding type.

2. According to the shape of the side surface of the load flat steel, it can be divided into: flat type, tooth type and “I” type, etc.

3. According to its use, it can be divided into general purpose grating and special purpose grating such as gutter cover, step plate, etc.

4. According to the material, the steel grating is divided into: stainless steel grating and carbon steel grating.

Steel Grating Features

1. High Strength & Load Capacity: Strong bearing performance, suitable for heavy-duty applications.

2. Corrosion Resistance: Available in hot-dip galvanized carbon steel or stainless steel, offering excellent rust and corrosion protection.

3. Excellent Ventilation & Drainage: High opening rate ensures good ventilation, lighting, heat dissipation, and drainage.

4. Anti-Slip & Safety: Serrated surface design provides slip resistance and ensures safety.

5. Lightweight & Durable: Combines low weight with high strength and long service life.

6. Easy Installation & Low Maintenance: Simple to install and cost-effective to maintain.

7. Versatile Design: Customizable in size, specifications, and surface treatments to meet various project requirements.

Steel Grating Application

Steel grating is widely used in industries such as alloy manufacturing, building materials, power plants, boilers, shipbuilding, petrochemical, chemical, general industrial plants, and municipal construction. It offers excellent advantages including good ventilation and light transmission, anti-slip performance, high load-bearing capacity, durability, aesthetic appearance, easy cleaning, and convenient installation.

In terms of applications, steel grating is commonly used for industrial platforms, stair treads, handrails, access floors, bridge walkways, overhead tower platforms, drainage covers, manhole covers, and road dividers. It is also applied in multi-story parking systems, fences for institutions, schools, factories, and sports facilities, as well as garden villas. Additionally, it serves as residential window guards, balcony railings, and safety barriers for highways and railways.

Note: Please leave your email address, our professionals will contact you as soon as possible!